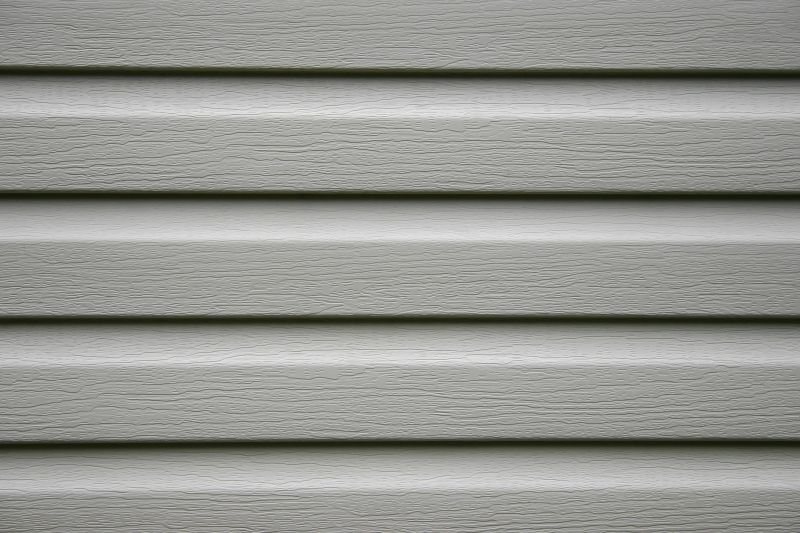

Optimal Timing for Cement Board Repairs

Cement board repairs are most effectively performed during periods of mild weather, avoiding extreme heat, cold, or moisture. Optimal conditions ensure proper adhesion and curing of repair materials, reducing the risk of future damage.

Spring and fall typically provide the best weather conditions for cement board repairs, with moderate temperatures and lower humidity.

Avoid repairs during heavy rain, snow, or freezing temperatures, as these can compromise the repair quality and longevity.

Schedule repairs when the forecast predicts several days of stable weather, allowing sufficient time for curing and setting.

Proper environmental conditions enhance the performance of adhesives and joint compounds used in cement board repair.

Ways to make Cement Board Repairs work in tight or awkward layouts.

Popular materials for Cement Board Repairs and why they hold up over time.

Simple add-ons that improve Cement Board Repairs without blowing the budget.

High-end options that actually feel worth it for Cement Board Repairs.

Finishes and colors that play nicely with Cement Board Repairs.

Little measurements that prevent headaches on Cement Board Repairs day.

Cement board is a durable, moisture-resistant material widely used in tiling and wall applications. Proper repairs are essential to maintain its structural integrity and prevent water infiltration. Timely maintenance can extend the lifespan of cement board installations, reducing the need for costly replacements.

Statistics indicate that regular inspection and prompt repairs can increase the durability of cement board by up to 30%. Environmental factors such as humidity, temperature fluctuations, and exposure to water significantly influence the timing and quality of repairs. Understanding these factors can help in planning maintenance schedules effectively.

A 60-second routine that keeps Cement Board Repairs looking new.

A frequent mistake in Cement Board Repairs and how to dodge it.

Small tweaks to make Cement Board Repairs safer and easier to use.

Lower-waste or water-saving choices for Cement Board Repairs.

| Factor | Ideal Conditions |

|---|---|

| Temperature | 50°F to 85°F (10°C to 29°C) |

| Humidity | 30% to 60% |

| Weather | Clear, dry days without rain |

| Time of Year | Spring or fall |

| Preparation | Several days of stable weather |

Filling out the contact form can provide tailored guidance on scheduling cement board repairs during optimal conditions. Proper timing ensures the durability and effectiveness of the repair work, preventing future issues and maintaining structural integrity.